At 15:18 on June 25, 2024, in Dizje, Turkey, when the electronic igniter burst into blue flames, the European photovoltaic glass industry extended its strategic layout to the bank of the Black Sea for the first time - a Turkish Duzce Cam ultra-white rolling photovoltaic glass production line, which was jointly contracted by China Building Materials International Engineering Group Co., Ltd. (CNBM), was constructed by China Building Materials International Engineering Group Co., Ltd. (hereinafter referred to as CNBM). This is not only the first show of Chinese-funded enterprises in the European photovoltaic glass market, but also means that "China Intelligent Manufacturing" has built a green energy golden bridge in the Eurasian continent.

Break through the siege · Mission and responsibility in the shock of life and death

Time goes back to 4:8 am on November 23, 2022, a magnitude 6.1 earthquake occurred in the Dizje Province, Turkey, with a depth of 10 kilometers. The epicenter is the location of the Duzce Cam project.

The project location is near the epicenter

"My mind was thinking, is there an earthquake? No, right? It was an earthquake. Then I rushed out quickly." As a member of the first design team to arrive, project manager Wang Min was still in lingering fears when recalling the scene during the earthquake. At that time, it was only two weeks before the pioneer design team arrived in Türkiye.

"My mind was thinking that Wang Min, a member of the earthquake design team and project manager, was still scared when recalling the scene during the earthquake. At that time, it was only two weeks before the pioneer design team arrived in Türkiye.

Exterior of Duzce Cam Photovoltaic Glass Production Line Factory

In addition to unexpected natural disasters, the on-site team also faces various other severe tests, from the installation of factory structure coupling equipment, production line hardware matching production processes, to the production indicators balancing energy consumption... But these are all resolved one by one with the team's efficient execution and the full technical support of the company headquarters. During the construction of the project, during the outbreak of the new crown epidemic, the on-site team often needed to hold meetings late at night in order to coordinate the time difference with the site in Türkiye. Relentlessly leaving day and night, forgetting to eat and sleep, the team is fighting a spirit of "especially able to endure hardships, fight, solve problems, and contribute."

Silk Road Spark · The strategic chess game behind the melting volume of 300 tons

Türkiye's glass market share has always been occupied by some established manufacturers. As the second largest flat glass manufacturer in Türkiye established in recent years, Duzce Cam has put into production two float glass lines in the past decade. Previously, they mainly relied on European technology and equipment, and their products were used in traditional construction, automobiles and other fields, and their technical standards were benchmarked against the European market. However, their goals are more than that.

In 2014, the Turkish government issued its own "Renewable Energy Development Plan (2013-2023)". The plan proposes to accelerate the construction of wind power and solar power generation facilities, strive to reach 20GW and 5GW by 2023, increase support for the photovoltaic industry, and encourage domestic Turkish companies to invest in the production of photovoltaic modules and related materials. Such a policy undoubtedly provides glass manufacturers such as Duzce Cam with an opportunity to turn to the new energy track. In 2018, they began to plan to deploy the photovoltaic glass market.

Duzce Cam photovoltaic glass production line

When deciding to invest in building a photovoltaic glass production line, they face two options. Traditionally, European countries such as Germany and Italy have accumulated a deep accumulation in the field of glass manufacturing, but the equipment and technical solutions of these companies are expensive; on the other hand, China's photovoltaic glass technology has risen rapidly in recent years and has become a global leader in photovoltaic glass technology and production, which has made them look to China. As the world's largest comprehensive glass engineering service provider, CNBM has completed a total of more than 60 glass production lines exported in many countries around the world, providing full-cycle engineering delivery solutions from design, construction, equipment supply, production commissioning, production and commissioning services to post-maintenance.

"In fact, our brands at home and abroad have already been made," said Hu Haojing, the head of project business negotiations with 18 years of overseas project experience. "The earliest HNG from Myanmar, Venezuela to India, and then to Bangladesh has already been put forward. Our brand of ‘CTIEC’ (China Triumph International Engineering Co., Ltd) has been launched. As long as the owner wants to build (glass) wire, he will definitely come to us, at least we are one of its major suppliers."

In 2018, the company's international business team established contact with Duzce Cam for the first time. After two years of tug-of-war negotiations, it finally signed the contract for the production line with the advantages of "full industrial chain service".

Ms. Ozturk, the factory director of Duzce Cam, who was previously in charge of one of the two floating lines, said: "Due to the lack of understanding of China before, the existing two floating lines have not used a single Chinese-made equipment during the construction process, all of which are European brands. And this time we decided to break this tradition entirely out of trust in CTIEC. As it turns out, CTIEC has not disappointed us!"

Continuous empowerment · From project delivery to value symbiosis

In June 2024, with the smooth ignition of the production line, Duzce Cam also became the glass manufacturing company with Turkey's largest photovoltaic production line, completing a gorgeous transformation from traditional manufacturing to new energy track. "We are fully confident that our future projects will continue with the same success. This is our first step towards a bigger goal," said Erdem Kavak, project manager at Duzce Cam.

Duzce Cam deepens cooperation negotiations with the company in 2025

In 2025, based on changes in demand in Türkiye's photovoltaic glass market, Duzce Cam decided to fully convert the 3.2mm ultra-white calendered glass it is being produced stably into 2.0mm products. Compared with 3.2mm glass, which is mainly used in traditional single-glass components, 2.0mm glass is more popular in the market for its advantages such as lightweight, long life, high power generation efficiency and suitable for dual-glass components. For this reason, Duzce Cam contacted CTIEC again to request technical support. The company attaches great importance to it and immediately dispatches professional technical service teams such as technology and self-control to assist the owners in carrying out the "tough" work of the production transformation of the entire process.

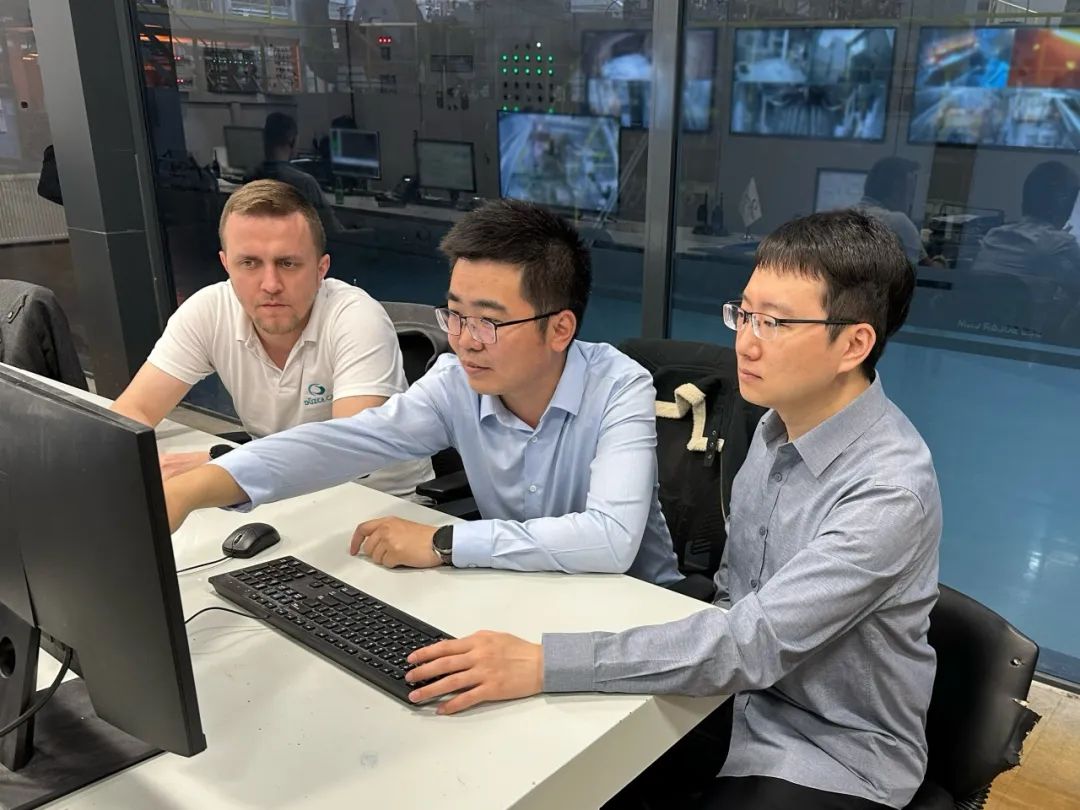

The team is conducting technical communication on production transformation

During the tough period, they worked day and night with the Turkish on-site personnel. In just one month, the edge loss rate of 2.0mm ultra-white rolled glass was reduced to 6.5%, and the yield rate reached 88.08%, successfully achieving technical compliance and stable mass production of glass slides. Duzce Cam expressed sincere gratitude to the technical services provided by the team. The two sides had in-depth exchanges on the future development of the Turkish glass market and reached a strategic consensus on long-term cooperation.

For CNBM, this is another successful example of actively responding to the "Belt and Road" initiative and promoting China's technology to "go global", and it is also a concrete practice of implementing the group's internationalization strategic deployment in "overseas reconstruction". From the battle of small inches in earthquake-resistant pits to the grand narrative of the Eurasian Energy Corridor, this production line not only melts ultra-white glass, but also looks like a green spark sown on the Anatolian Plateau. When China's technical standards and Turkey's location advantages blend here, it will surely ignite the prairie fire of the Eurasian New Energy Industrial Belt and let the green and sustainable development of the Eastern wisdom illuminate the new journey of the Silk Road.

Reporter's Notes | Light and Heat after the Echo

Standing in the factory in Dizje, Türkiye, watching the seeker sending out of the annealing kiln area, I can't help but recall the arduous journey of the construction of this photovoltaic glass production line. From the reshaping of the earthquake in 2022, to the successful ignition in 2024, and now 2.0mm glass is successfully launched, it is not only a production line, but also a bridge connecting Chinese technology and the European market.

Recalling the interview, project manager Wang Min mentioned that the night of the earthquake, warehouse shelves were dumped and glass fragments were scattered all over the ground. The first thing she thought of was the safety and follow-up response of the project. This calmness and responsibility make me see the high sense of responsibility and mission of CNBM engineers.

During the construction process, every detail is full of challenges. Any construction deviation may affect the entire production process and product quality. However, it is the team's refined management and adaptability that has allowed this photovoltaic glass production line to be successfully implemented and broken the technical barriers of the European market.

Behind the daily melting volume of 300 tons is the determination and perseverance to sharpen a sword for three years, the struggle and courage for two years online and offline, and the wisdom and sweat of a generation of engineers. When the blue flame is lit, I feel as if I see that photovoltaic glass is illuminating not only the factory, but also the firm pace of China's intelligent manufacturing to move towards the world.